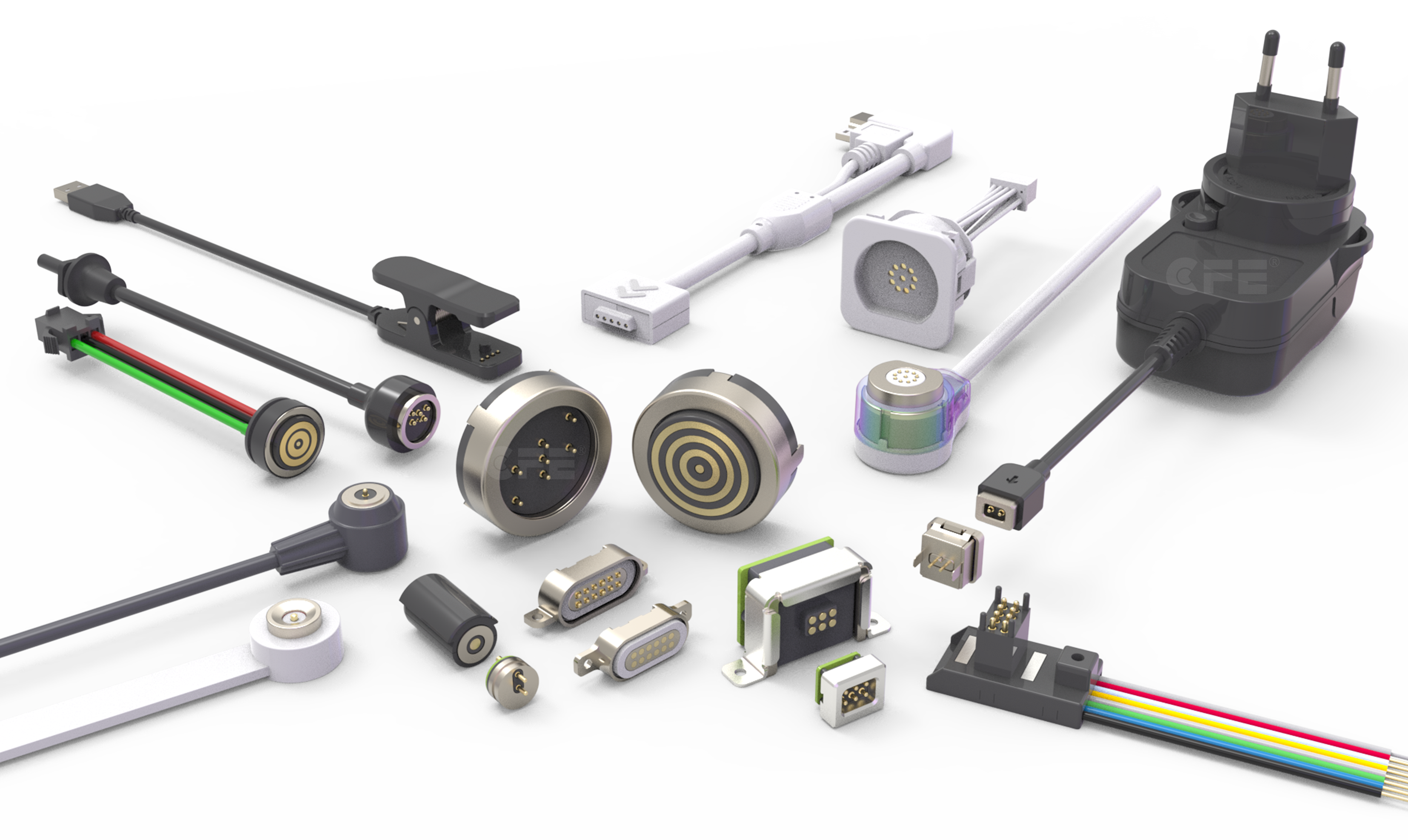

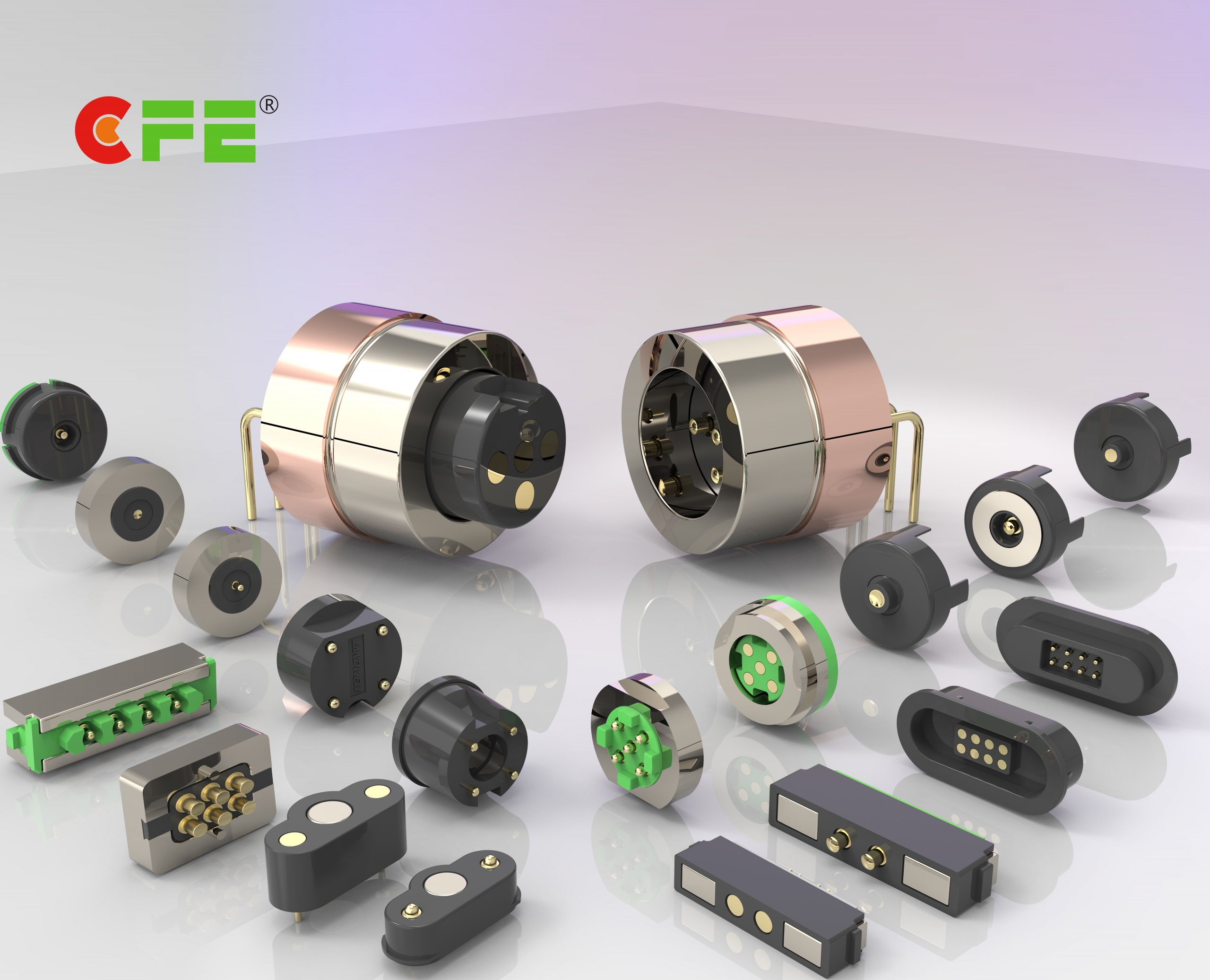

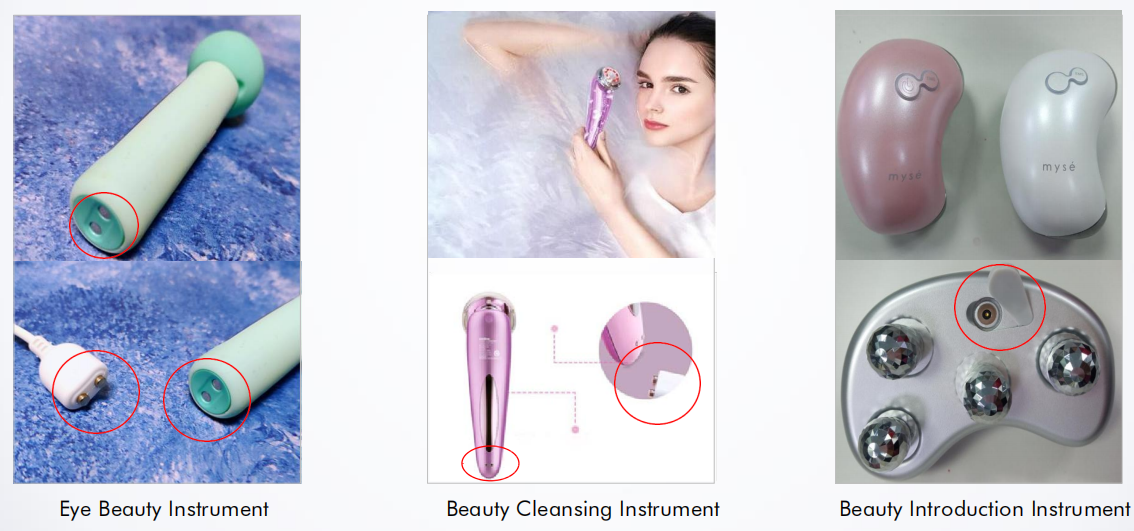

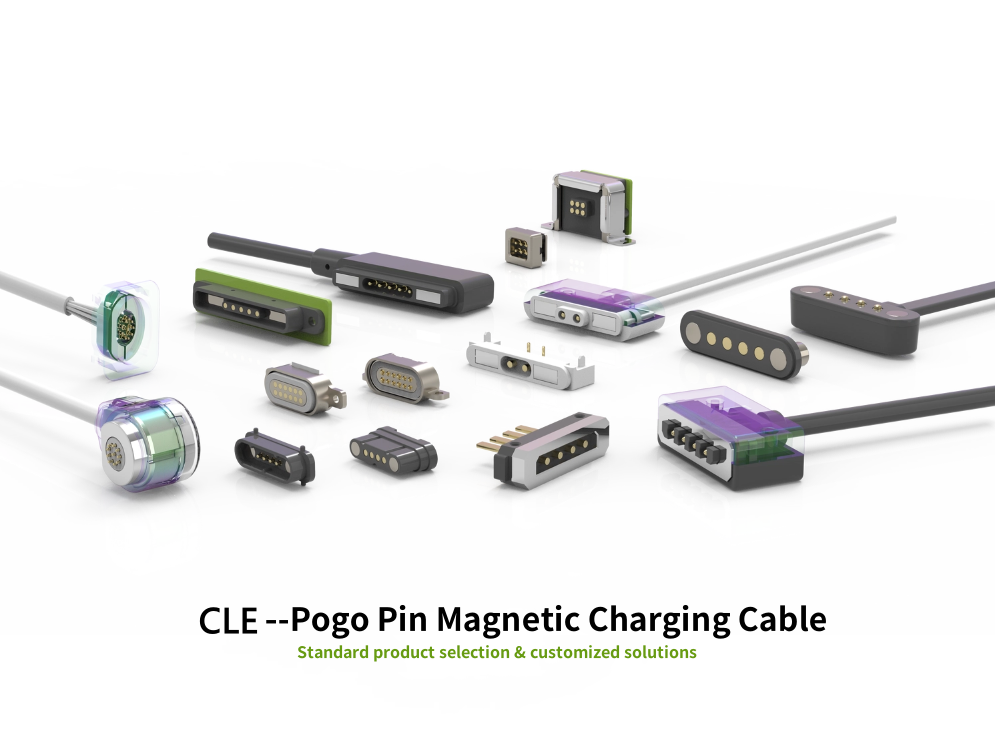

As an indispensable connection device in electronic products, electronic connectors are used in a wide range of applications that are amazing. Behind them, every detail of the process embodies the wisdom and sweat of the craftsmen, and they constantly pursue the ultimate realm of excellence. Electronic connectors are assembled and combined with precision hardware parts and plastic parts. Therefore, plastic molding undoubtedly plays a pivotal role. Pogopin magnetic charging cable is mainly composed of magnets, pogopins and plastic parts. Therefore, plastic molding process is very important in the production process of plastic parts. CLE will use different plastic molding processes according to the different needs of customers for products.

Plastic molding is the process of making various forms of plastic into products or blanks of the desired shape. There are more than thirty molding methods. The choice of plastic molding is mainly determined by the type of plastic (the plastic type here refers to thermoplastic or thermosetting), the starting form, and the shape and size of the product. At present, CLE uses a variety of processes for product plastic molding, mainly injection molding and insert molding.

-

Injection molding

The principle is to add granular or powdered raw materials into the hopper of the injection molding machine. The raw materials are heated and melted into a flowing state. Under the push of the screw or piston of the injection molding machine, they enter the mold cavity through the nozzle and the pouring system of the mold, and harden and shape in the mold cavity.

Advantages: Injection molding can handle highly complex parts and provide consistency. Injection molding can improve production efficiency and speed. Compared with other methods, the injection molding process is faster and the high production output makes it more effective. Injection molding can reduce waste. Injection molding has low labor costs. Injection molding shortens product development time, etc.

-

Insert molding

Insert molding refers to the process of injecting resin after inserts of different materials are prepared in advance in the mold. The molten material is bonded and solidified with the insert to form an integrated product. This is also called in-mold injection molding.

Advantages: It is convenient to modify the mold, and inserts can be added or removed at any time. It is convenient for the mold to be vented, so that the quality of the products produced is higher and the occurrence of defective products is reduced. It is convenient for mold processing. It increases the service life of the mold. When the insert is damaged, it can be solved by replacing it, without having to replace the entire mold.

CLE/CFE has more than 15 years of experience in the PogoPin connector and magnetic connector industry, integrating R&D, production and manufacturing, providing customers with high-quality spring pin PogoPin magnetic connection charging and connection solutions to achieve efficient and stable transmission and connection.