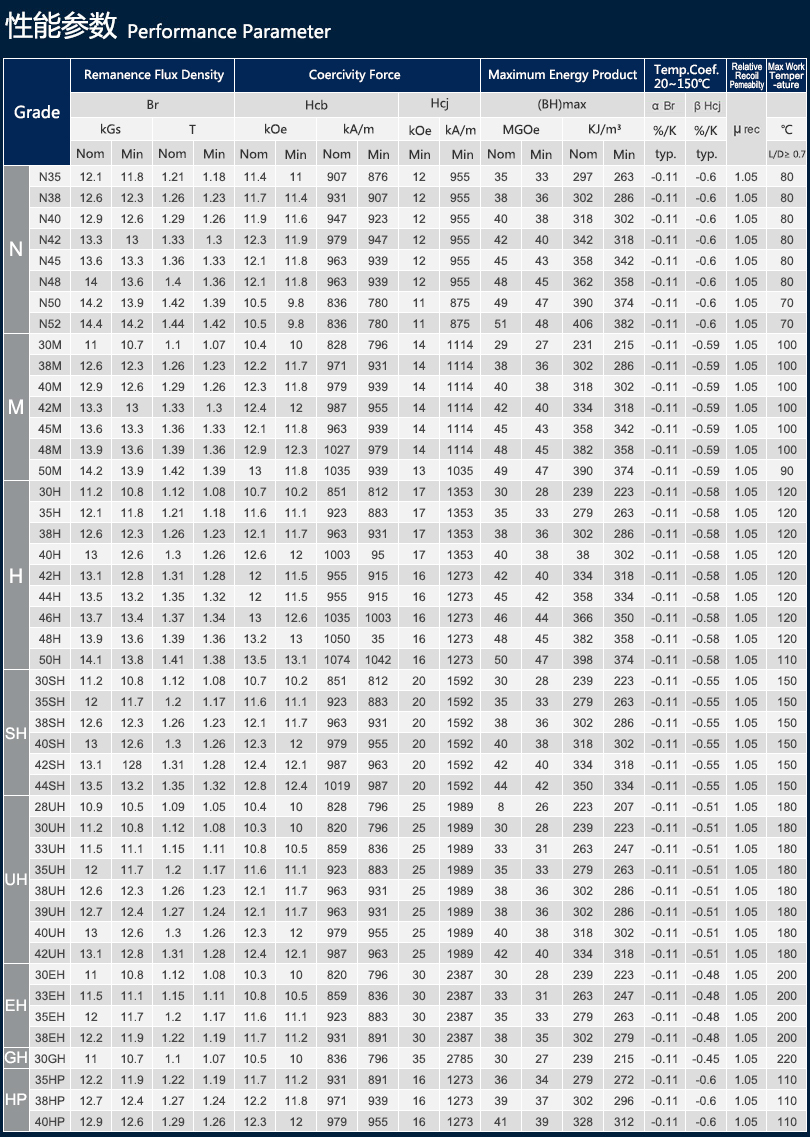

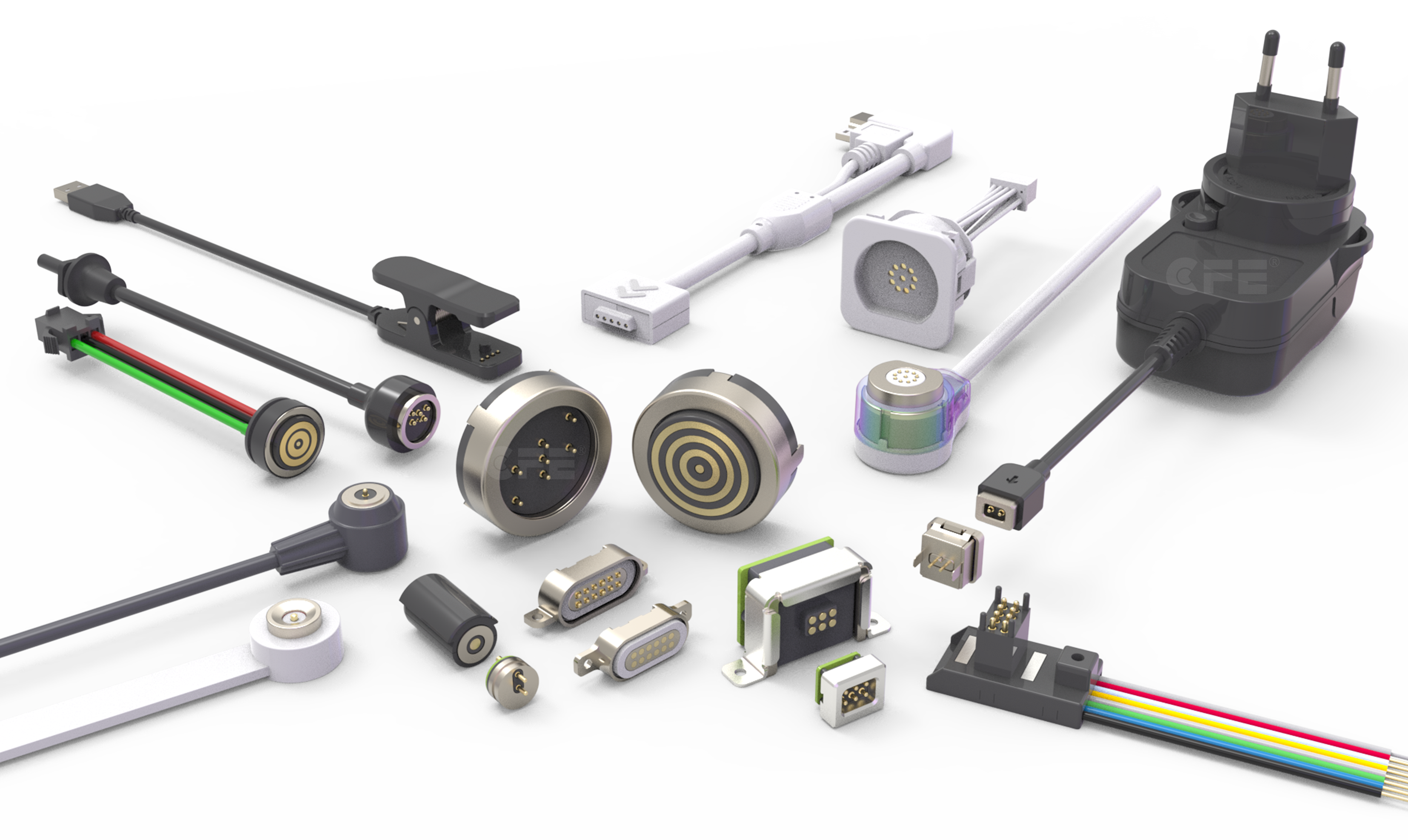

Magnetic connector, also known as magnetic interface, is an electronic device interface technology that uses magnetic force to achieve convenient and fast connection. Its main feature is that it uses the attraction of the magnet so that the two parts of the connector can automatically adsorb and complete the electrical connection without precise alignment. The magnets in CLE’s magnetic products are mainly neodymium iron boron magnets (NdFeB magnets), also known as rare earth permanent magnets, which are the materials with the largest magnetic energy product in the world. NdFeB magnets are widely used in electronic products such as hard drives, mobile phones, headphones, and battery-powered tools. NdFeB magnets are divided into sintered magnets and bonded magnets. CLE products are mainly sintered NdFeB magnets. NdFeB magnets are divided into several grades according to the maximum magnetic energy product. Each grade has different performance according to the ratio of rare earth elements. For example, the higher the grade, the greater the magnetic attraction… The specific magnetic attraction of the magnet can be referred to the magnet grade table.

What should you pay attention to when choosing NdFeB magnets?

When selecting NdFeB magnets, CLE is mainly considered from two aspects: operating temperature and magnet grade.

- Operating temperature

CLE mainly customizes pogopin magnetic connector products according to customer requirements. Most of the products are semi-finished products, and customers need to assemble them into finished products through the process. For example, in the processes of reflow soldering, wave soldering and manual soldering iron, high temperature will cause the magnet to demagnetize, resulting in a decrease in adsorption force. At this time, attention should be paid to the design of the product to avoid affecting the magnet. Another thing is that the magnet is used in a high temperature environment, such as being soaked in boiling water. At this time, high temperature resistant magnets should be selected. If there are more stringent use environments, CLE will also provide suitable solutions based on the customer’s application scenarios.

2. Magnet grade

In terms of magnet grade, different grades of magnets have different adsorption forces. However, the size of the adsorption force is also directly related to the area, volume, and distance between the adsorption surfaces of the magnet. For example, the adsorption area of the magnet is directly proportional to the adsorption force, and instead of increasing the magnet grade, it is better to increase the magnet adsorption area, so that the adsorption force increases faster. If the adsorption area and the magnet volume are the same, the adsorption force can be increased by increasing the magnet grade. Of course, the adsorption distance is also an important factor. Beyond a certain distance, the adsorption force will drop sharply. The size of the adsorption force is provided by the magnet, but how large the adsorption force should be is the real standard for testing whether the product is easy to use.

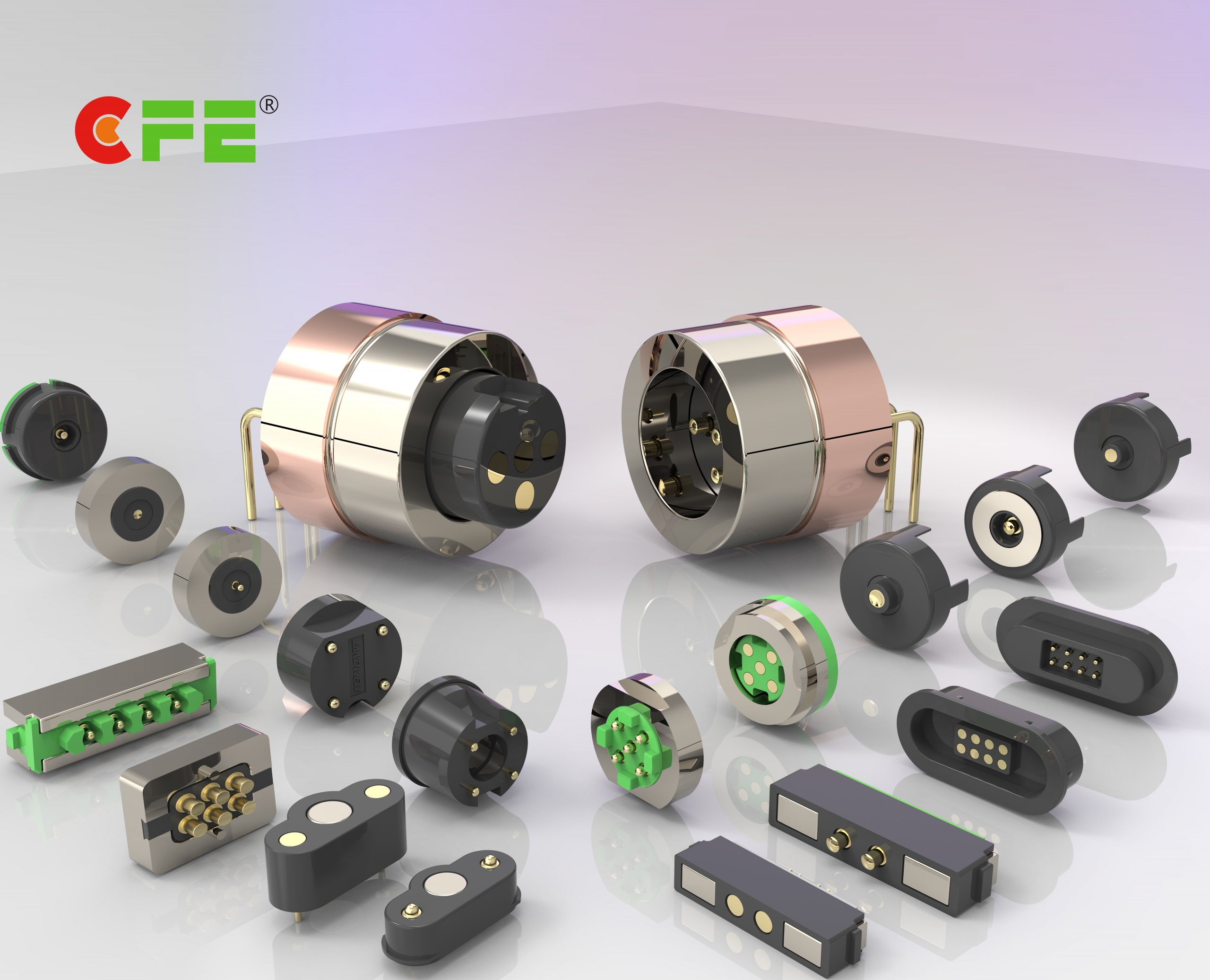

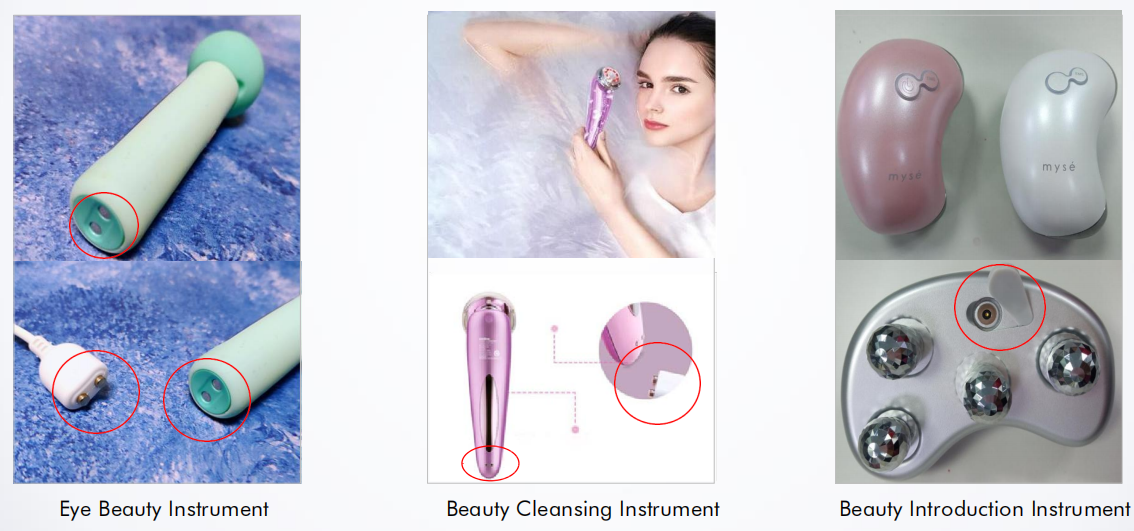

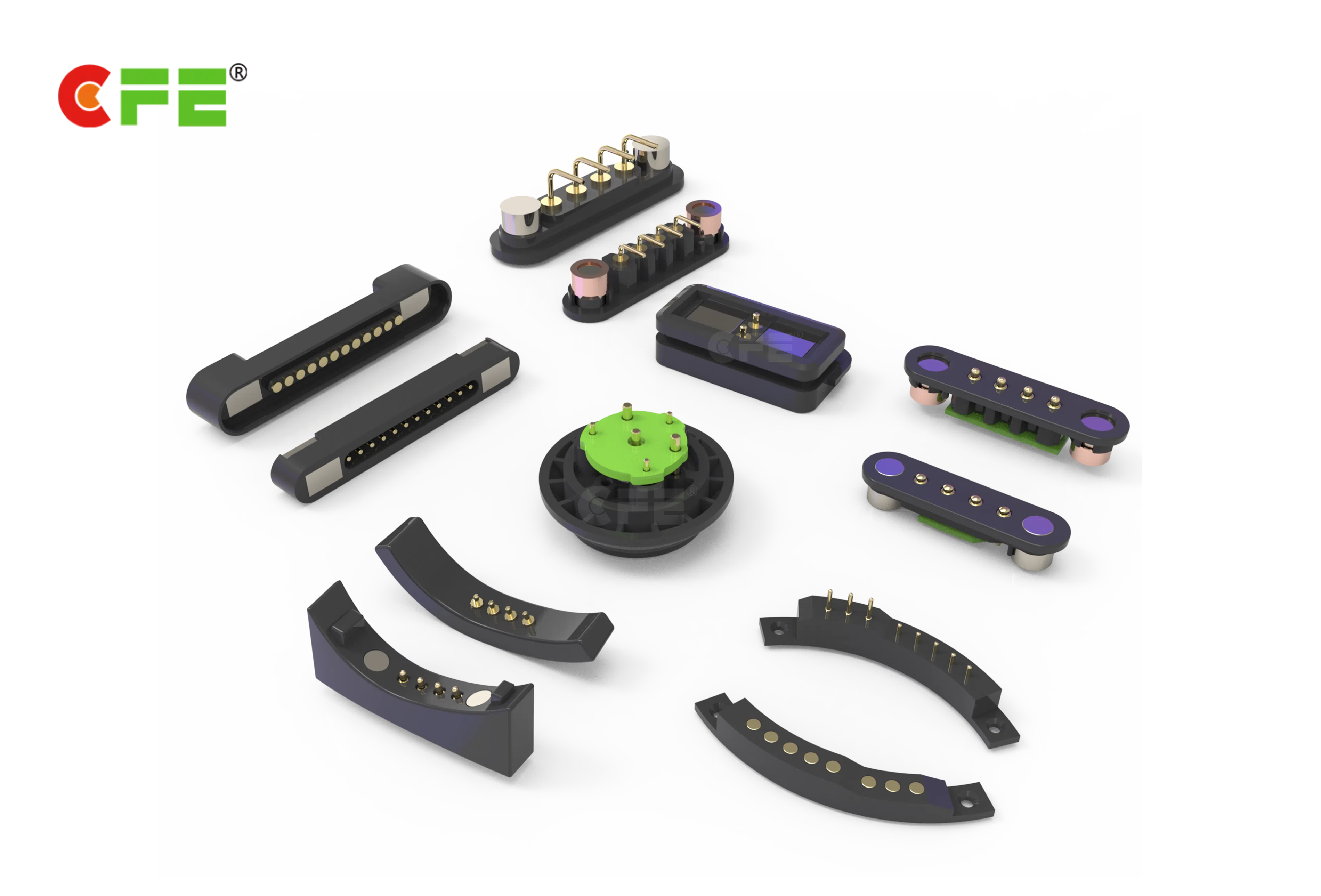

Regarding how to define adsorption force, CLE has professional solutions for product applications in various fields through exploration and communication with customers. CLE has been involved in magnetic connector customization since 2011. Combining the original pogopin connector technology capabilities, magnetic connector solutions have accumulated more than 200 fields and thousands of product designs.